|

I chose to remove the original solder points before installing

the 7-pin DIN sockets. If you decide to do this, heat each one

until it is smoking hot, then immediately remove it with pliers.

They should come out with practically no resistance; otherwise there is

a possibility of damaging the printed circuit board. It's easier

to just leave them in place, but I think the job looks tidier if they

are removed.

If you click the photograph at left to see the larger version, you will

notice pairs of pre-drilled holes for connectors at locations H, J, and

K. I made a cardboard template to locate these

accurately, then pushed an awl through the holes in the template to

mark where I needed to drill. Before drilling, remove the stop

filter cards if they will be in the way.

When drilling the holes, use a 3/32" bit and be very careful to keep

the drill exactly vertical. If in doubt, its better not to err in

the direction that causes the bit to break through the wood behind the

terminal boards. If any holes break through or turn out to be in

the wrong place, plug them with round wooden toothpicks then drill

again.

|

|

|

|

|

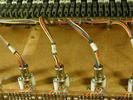

I mounted the sockets with the ground tabs

facing the back of the organ, so I decided to wire each socket in

counterclockwise order as seen from the bottom. Going

counterclockwise from the ground tab, the sequence is brown, red,

orange, yellow, green, blue, violet.

|

|

|

|

To save time and wire, I made a template showing how long to cut each

color of wire for the left and right DIN connector locations. First

cut a thin piece of cardboard to about 3 1/4" (85 mm) square. Cut two

pieces of each color wire to the same length as the template, strip them about 5/16 inch (7 mm), then

solder the wires to two DIN sockets in the color sequence described above.

Mount one of the two sockets on the right pair of holes (as seen from

the back of the organ) above a terminal board. Route the wires to

the terminal board, cut them to length (but save the cut off ends!) and

strip about 5/16 inch (7 mm) then solder them to the top row of

terminals in the left to right sequence brown, red, orange, yellow,

green, blue, violet. Set aside the cut off ends in a safe place,

then install the second socket on the left side in the same way and

save the cut off wire ends from this socket in a separate place.

(If you forget which is which, the cut off end for the brown wire will

be longer on the left socket.)

Note:

In the picture, I show two sockets mounted at

location W, but locations W and V only need one socket each unless you

are using or planning to use Devtronix tone generators. If you

are using Schober generators for both keyboards, mount pairs of sockets

at locations U through H.

|

|

|

|

|

Tape the cut off ends of the wires from the right socket to the piece of

cardboard so that one end of each wire is even with the edge of the

cardboard. Label this side of the template Right and GT or

Great. In the same way, tape the cut off wire ends from the left

socket to the reverse side of the cardboard, and label this side Left and SW or

Swell. (Never mind that the cardboard depicted at left is labeled incorrectly -- my mistake!)

|

|

|

|

Now pre-wire and install all the right (Great)

sockets, connecting them to the top row of terminals in the left to

right sequence brown, red, orange, yellow, green, blue, violet.

To make this less tedious, you can pre-wire three to five sockets, then

install them before pre-wiring more. I did about three per

evening, so it took about four evenings.

|

|

|

|

Once all the Great sockets are in place, it's a

good time to temporarily re-install the Great keyboard and solder on

the DIN plugs. Because the the wires from the keyboard have to

make a fairly sharp turn as they leave the connectors, I removed the

rubber sleeves from the connector shell. To solder each

connector, disassemble it and slip the shell over a wire bundle coming

from the keyboard. Set the screw aside in a safe place -- small

metric screws are hard to obtain! Carefully remove the small

metal piece from the connector pin assembly, and temporarily plug the

pin assembly into one of the DIN sockets. Now arrange the bundle

so that looking at the ends of the wires, the wires are in the same

sequence counter clockwise as on the socket (brown, red, orange,

yellow, green, blue, violet). You may need to slip some of the

wires out of the last piece of tape on the bundle and re-insert them;

possibly the bundle will need to be re-taped. Now cut off the stripped

ends of the wires to even out the lengths and strip approximately 1/16"

(2 mm) of insulation from each one. Beginning with the brown

wire, solder the wires to the pin assembly. Note that as seen

from the top, the color sequence will appear clockwise rather than

counter clockwise. Check the location of the brown wire on the

socket to make sure!

When all the pins are soldered, carefully re-install the small metal

piece on the pin assembly, then slip the assembly into the connector

shell and re-install the screw.

|

|

|

|

At this point, you may want to begin cleaning the keyboard contacts,

if you have not already done so. During cleaning, either keyboard

can be connected temporarily to the Great DIN sockets for testing.

Wiring the sockets for the Swell is the same as the Great, except the

the sockets are mounted on the left at each circuit board location and

the wires are soldered to the middle row of holes on the circuit board.

|